Renewable Gasfield

Project description

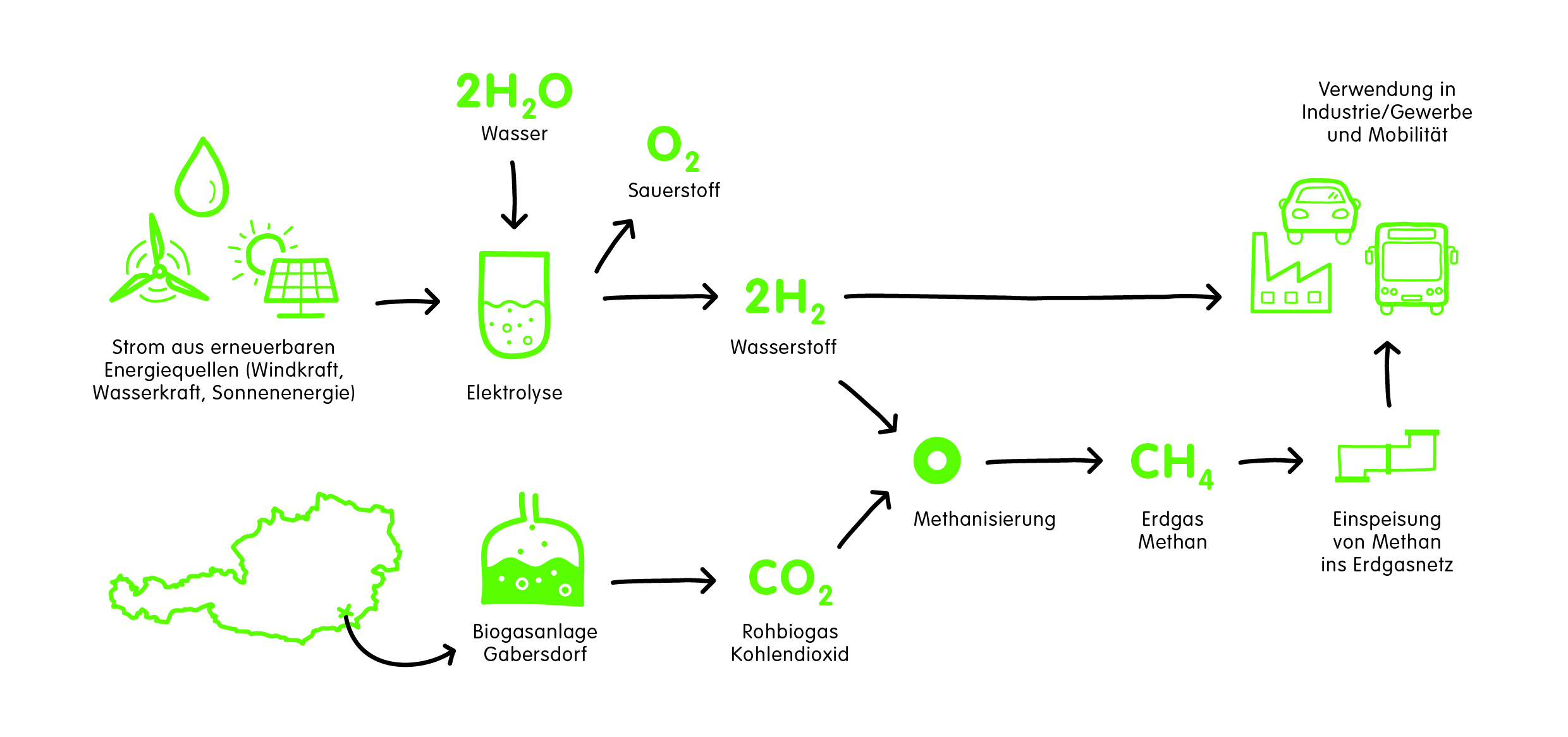

The decarbonization of the power supply and the shift from carbon-based energy sources to renewables lead to major changes in the energy economy to secure a long-term energy supply. Due to the high volatility of wind power and photovoltaics (PV) an increased energy storage demand is required. The existing Austrian natural gas grid offers an enormous storage potential. Green energy from wind power or PV is used in water electrolysis for hydrogen (H2) production and its following methanation of carbon dioxide for synthetic natural gas (SNG) production.

The project Renewable Gasfield – a demonstration project as part of the energy model region WIVA P&G – combines green hydrogen production via electrolysis and load-flexible, double stage catalytic methanation on a large scale, and distributes the produced SNG in the existing gas grid.

A PEM-Electrolysis produces green hydrogen from regenerative resources, mainly a 1 .5 MW PV field onsite. H2 is either used for a 350 bar hydrogen filling station or for a methanation process of carbon-rich biogas. In the southern part of Styria (Austria) an existing biogas plant is operating at half capacity. Coupling it with a load-flexible methanation will enable the generation and storage of SNG in the gas grid. Experimental results of a laboratory scale plant already showed nearly a 100% CO2 conversion from the input biogas to methane and water.

For the methanation process ceramic honeycomb catalysts are used. A pretreatment of the biogas by adsorption (deep desulfurization) prevents catalyst poisoning and saves the usually necessary and cost-intensive CO2-separation.

A PEM-Electrolysis produces green hydrogen from regenerative resources, mainly a 1 .5 MW PV field onsite. H2 is either used for a 350 bar hydrogen filling station or for a methanation process of carbon-rich biogas. In the southern part of Styria (Austria) an existing biogas plant is operating at half capacity. Coupling it with a load-flexible methanation will enable the generation and storage of SNG in the gas grid. Experimental results of a laboratory scale plant already showed nearly a 100% CO2 conversion from the input biogas to methane and water.

For the methanation process ceramic honeycomb catalysts are used. A pretreatment of the biogas by adsorption (deep desulfurization) prevents catalyst poisoning and saves the usually necessary and cost-intensive CO2-separation.

Project goals

Methanation experiments with biogas at variable flowrates by using commercial bulk catalyst show an achievable goal of constant >99% CO2 conversion with varying availability of hydrogen. Further experiments will be carried out to compare the performance of wash-coated honeycombs with the commercial bulk catalyst to ensure an economic feasible hydrogen surplus and a constant CO2-conversion during operation. The technology will be tested in demonstration scale at Gabersdorf in Southern Styria.

Factsheet

Project video

Gallery

Project News

Eröffnung der ersten öffentlichen Produktion für „grünen“ Wasserstoff in Österreich

Energie Steiermark setzt auf neue Nachhaltigkeits-Partnerschaft mit der Industrie (9.Mai 2023) Graz/Gabersdorf...

WIVA Jahresveranstaltung – Vorträge

Die WIVA P&G Jahresveranstaltung fand am 17. und 18. Oktober 2022 in Villach statt.

WIVA P&G bedankt sich bei den Vortragenden und den TeilnehmerInnen.

Die Vorträge für alle zum Nachlesen finden Sie hier im Programm verlinkt:

Renewable Gasfield – Der Baustart ist erfolgt

Mit Renewable Gasfield wird ein wichtiger Schritt für die Produktion und den Einsatz von grünem Wasserstoff in der...

Video: Standardisierte Biogasaufbereitung & Methanisierung

Nachschau zum ÖVGW Seminar Gas Digital 2021. Univ. Prof. DI Dr. Ing. Markus Lehner Lehrstuhl für Verfahrenstechnik des...

Video: Wasserstoffaktivitäten der Energie Steiermark GmbH – Projekt Renewable Gasfield

Wasserstoff Aktivitäten der Energie Steiermark, Projekt Renewable Gasfield Hier der Beitrag von DI Klaus Neumann,...